Looking to improve the efficiency, durability, and cost-effectiveness of your energy storage systems? In battery enclosures and related sheet metal components, small design and material choices can make a big difference – especially when space is limited, thermal expansion is a factor, or assembly needs to be fast and reliable.

We support you with sheet metal solutions that combine deep drawing and progressive stamping technologies.

These enable:

- Lighter, stronger housings with integrated features

- More efficient use of materials with less waste

- Simplified and faster assembly processes

- Scalable production from prototypes to high volumes

Our experience in the energy storage sector helps avoid common design pitfalls and reduce total cost of ownership. From early-stage design consultation to serial production and logistics, we help you build smarter – and stay competitive.

Optimized sheet metal components for battery modules:

- Busbars and connectors – Copper and aluminium components for efficient power distribution and conductivity

- Battery covers and enclosures – Deep drawn and stamped solutions providing protection

- Cooling components – Custom-engineered parts for optimal thermal management

- Structural supports and brackets – Lightweight yet robust elements ensuring battery module integrity

Want to dive deeper into how smart sheet metal design improves battery module performance? We have made a brochure that gives you concrete examples, technical details, and design insights to support your next project.

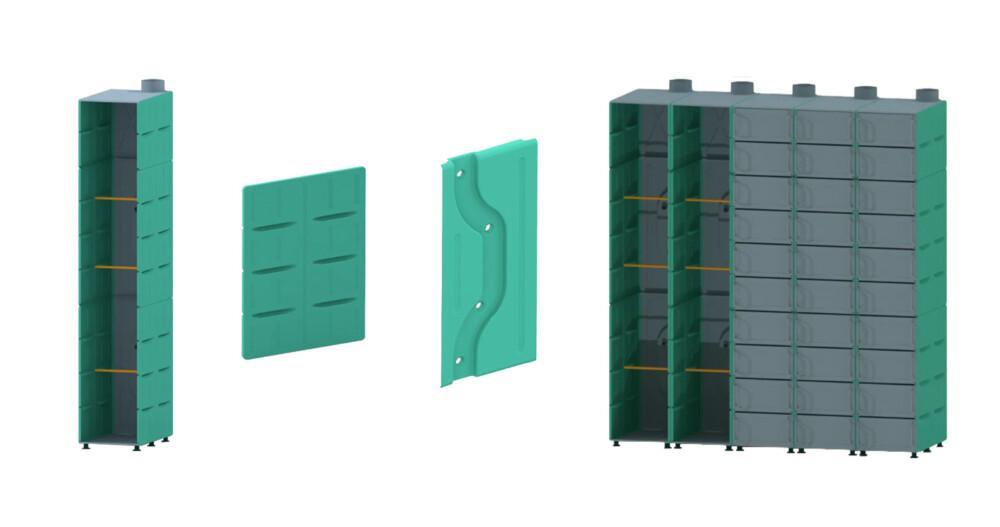

Tailored to your needs – battery racks

In demanding applications like battery modules, every design decision matters. From material choices to component integration, small improvements can lead to big gains in durability, assembly speed, and overall system efficiency.

By using proven sheet metal solutions tailored to your needs, you can accelerate your time to market through a smooth transition from concept and prototyping to serial production and delivery. At the same time, you improve cost-efficiency by reducing material usage minimizing the number of individual components and simplifying the assembly process.

Want to learn more about how to design and manufacture efficient, scalable rack structures for energy storage systems? This brochure covers key design principles, materials, and manufacturing methods – all tailored to meet industry demands.

Technologies and capabilities support your development

Whether you’re refining an existing design or starting a fresh one, we’re here to help you move forward with confidence – and measurable results. Our solutions significantly reduce material usage, production time, and CO₂ emissions, helping you meet both environmental and business goals.

Our modern technologies and years of experience are the key to smart solutions.

Deep drawing – Enables strong, lightweight battery housings with built-in features that reduce assembly steps

Progressive stamping – High-precision, scalable production ideal for large volumes

Design support – Practical guidance to help you simplify structures, avoid pitfalls, and reach your performance targets faster

Get inspired – and get results

Want to see what optimized energy storage components could do for your business? Activate our exclusive material to explore real-life examples, practical insights, and design tips to take your next project further.

Material includes:

- Application case examples

- In-depth technical knowledge

- Actionable design improvements

Click to get access to the material – and start improving your energy storage solutions today!

Got questions or ideas you’d like to discuss? We’re happy to help – whether you’re just exploring options or already deep in development.

Want to boost performance, cut costs, and streamline your energy storage system’s design? Unlock the access!

Discover how smart engineering choices can make your battery systems lighter, stronger, and more cost-effective – without compromising performance.

Lue lisääHome of manufacturing

Home of manufacturing Imagine a manufacturing partner, who understands your needs, where challenges are turned into opportunities, and each solution…

Read moreEnabling your success in electrification

There are many important aspects to be considered in the design and operation of process pipelines, and lock washers play an important role in securing joints under varying weather conditions.

Read more