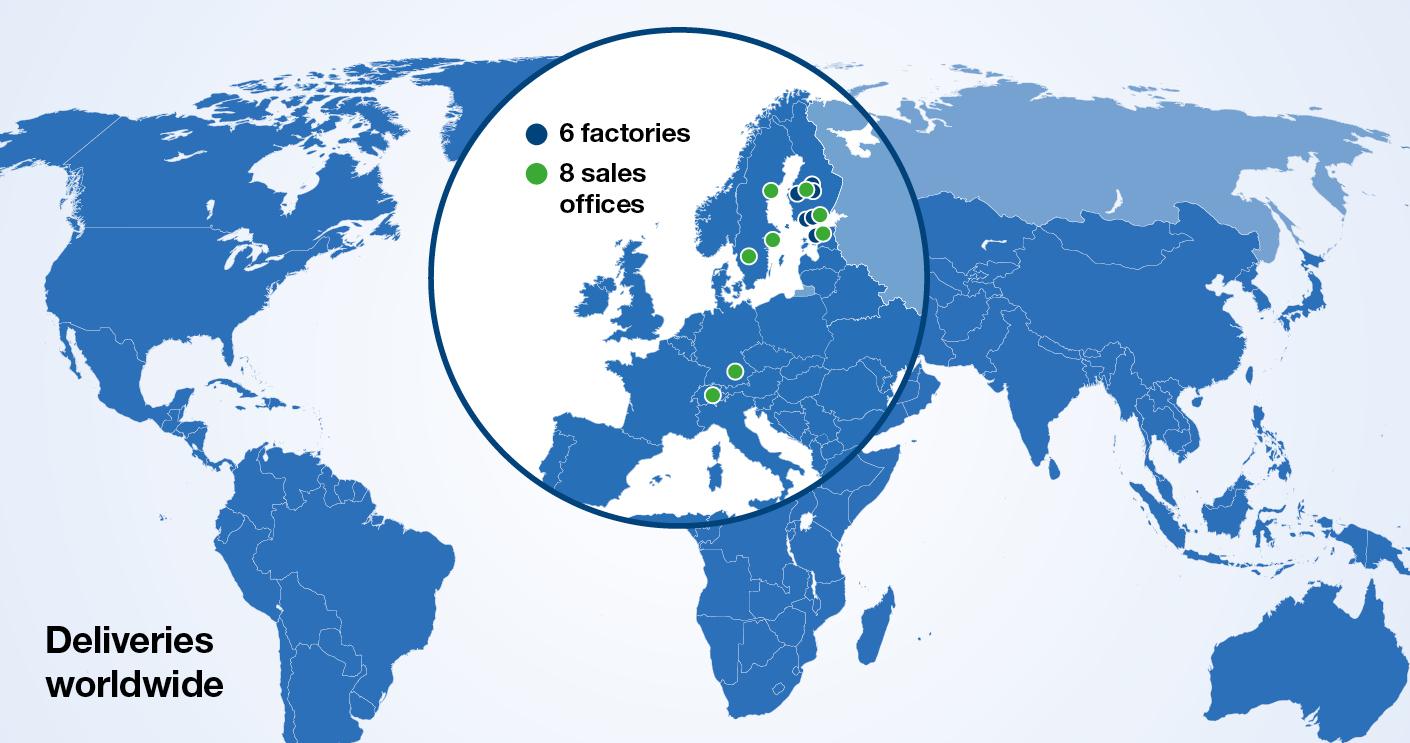

In today’s fast-paced manufacturing landscape, technologies evolve, regulations tighten, and customization becomes the norm. Production runs are shorter, and the ability to respond quickly to change is more valuable than ever. At Meconet’s Äänekoski plant in Finland, our operations are tailored specifically for low-volume manufacturing – with a focus on flexibility, efficiency, and cost-consciousness.

Laser cutting– driving agility and speed

The possibility to use 2D/3D-laser is a key enabler of flexibility. It allows for faster iterations, fewer tooling dependencies, and rapid adaptation to design changes. Especially in complex assemblies, late-stage design tweaks are often unavoidable – and with laser technology, they can be implemented efficiently without disrupting the overall production schedule.

Key customer benefits of our laser capabilities:

- Modifications possible at any production stage, with minimal cost impact

- Shorter lead times, better adaptability to evolving requirements

- Ideal for dynamic industries and tailored product variants

Whether your component requires deep drawing, cold forming, or another precision forming process, we carefully select the optimal production technology based on efficiency, quality, feasibility, and cost-effectiveness. By aligning technical capability with your product’s unique requirements, we deliver tailored manufacturing solutions that ensure performance, reliability, and value.

Modern equipment enables smart manufacturing

The Meconet plant in Äänekoski is built around modern, flexible equipment designed for agile production.

- 3D lasers (x6): Precise cutting with minimal tooling costs. Excellent for small batches and fast turnarounds.

- 2D laser: High-precision cutting, low material waste, and wide material compatibility.

- 1,600-ton servo press & automated deep drawing line: High control accuracy, pulsating forming, and consistent automated output.

- Automated riveting: Consistent quality, reduced manual labor, and cost efficiency.

- Welding automation cell: Fast production cycles, repeatable quality, and full integration with other automated processes.

When your product design keeps evolving, or when you’re looking for small to mid-scale production with high quality and quick response – Meconet Äänekoski delivers. We’re here to ensure your components meet every technical, economic, and timeline demand – even when the goalposts move mid-project.

We offer solutions tailored for your specific volume needs – built around your product and your priorities.

Want to speed up your product development and optimize production? Unlock the access!

We have compiled the material for you on prototypes and small series production. Take advantage of these tips and optimize your production and product development with our help!

Read more